Press-brake bending and clinching

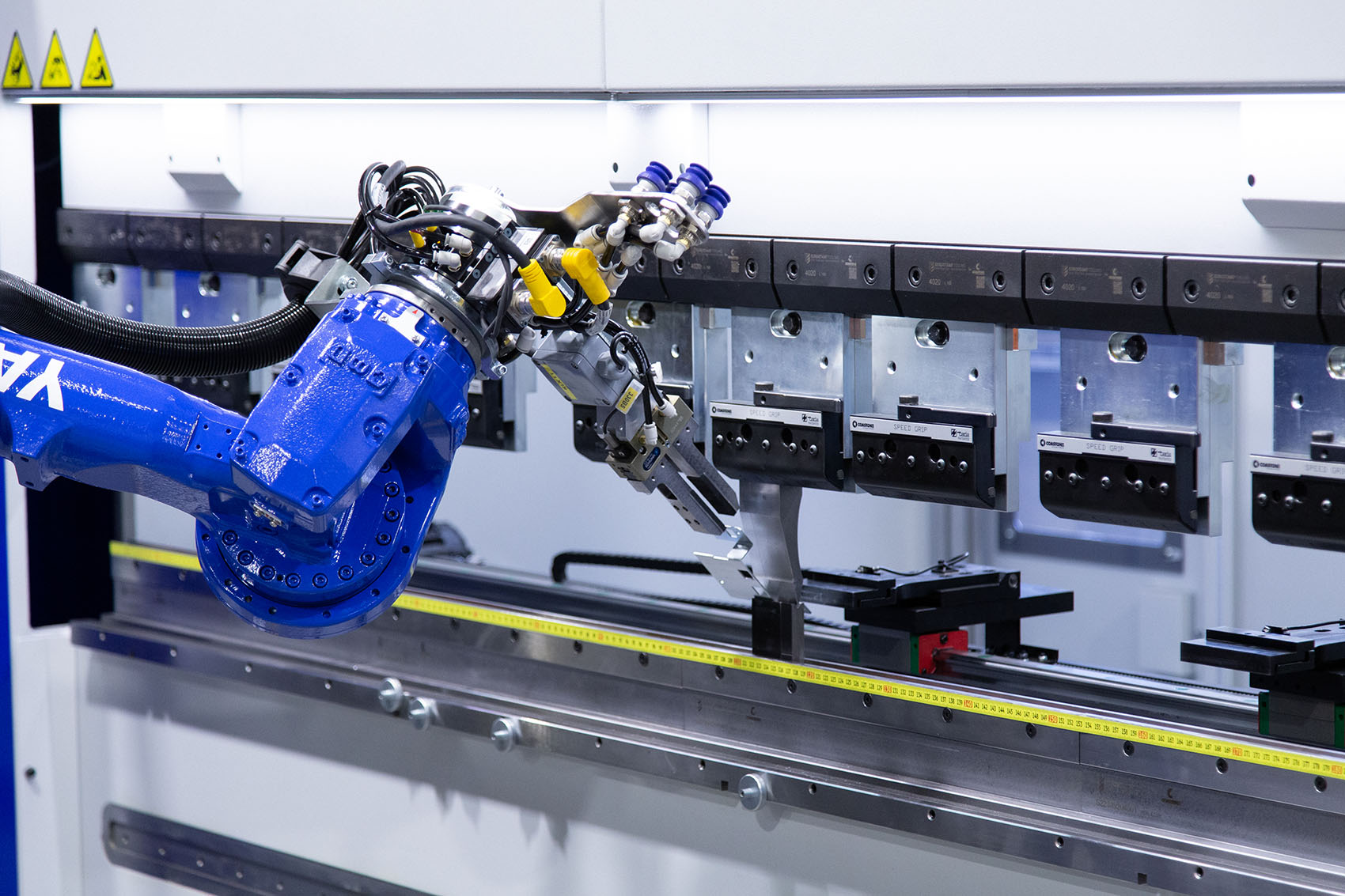

We do press-brake bending and clinching in an automated robotic unitSheet metal bending and press-joints

Bending

Bending is done on multi-axis CNC machines and, if necessary, we bend larger series of repetitive products in a robotic bending unit. The robotic bending unit is equipped with a Coastone G20 press brake with a bending force of 75 tons and a bending length of 2040 mm and a Yaskawa/Motoman GP50 industrial robot with a load capacity of 50 kg.

Clinching

Clinching is a mechanical sheet metal joining method in which two or more sheets are joined together without the use of additional materials such as welding wire, rivets or adhesives. Clinching is an efficient, cost-effective and environmentally friendly way to join metal sheets, especially in sheet metal applications. We perform clinching in an automated robotic unit for large series and manually for individual pieces.

Advantages of clinching

- No thermal effects: Unlike welding, clinching does not cause thermal effects on the materials, which reduces thermal stresses and deformations.

- Environmental friendliness: No additives or chemicals are used and the process is energy efficient.

- Suitable for most materials: Suitable for joining various materials such as steel, aluminum and copper.

- Cost-effectiveness: Reduces material consumption, as the method does not require welding wire or other additional materials.

The Coastone press brake and Yaskawa robot unit handle the bending of even large product series in an automated manner.

The automated clinching unit can be programmed to make durable and high-quality joints, for example, in cases made of thin sheet metal.

Brilliant mechanics factory

See also our production methods

Steel and aluminum cutting

We cut sheet metal in a versatile and efficient manner in our own production.

Welding and laser welding

Our production includes versatile welding machines and technology for welding products made from sheet metal.

Press-brake bending and clinching

New! We perform press-brake bending and clinching in an automated robotic unit.

Machining

Machining plays an important role in the manufacture of mechanical assemblies.

Coating and painting

We also do coatings and powder coatings for sheet metal products under one roof.

Screen printing and laser marking

Fine texts and graphics on the surface of sheet metal products by printing or laser marking.

Assembly and testing

In addition to high-quality components, we offer our customers mechanical and electrical assembly and testing services.

A reliable partner

We are a challenger of tomorrow who wants to succeed together with our customers today!

Jukka Kotamäki

Sales / Head of Unit

+358 40 501 7799

jukka.kotamaki(at)elekmerk.fi