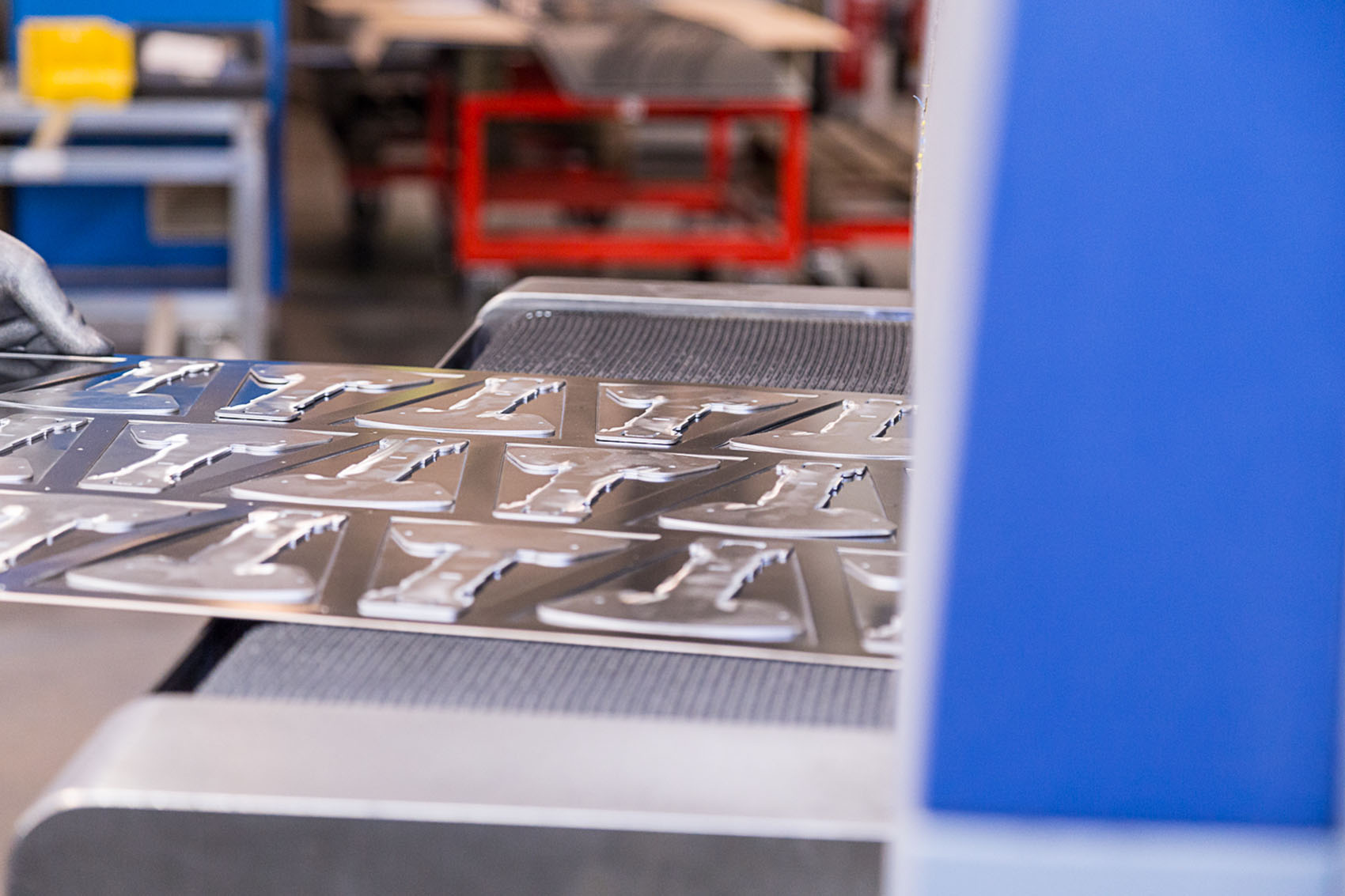

Steel and aluminum cutting

We cut sheet metal in a versatile and efficient manner in our own production.Sheet metal cutting

In steel parts (FE, galvanized, RST/HST) we focus on thicknesses of 0.5 – 4.0 mm and we cut aluminum up to 20 mm thick. We cut thinner thicknesses by punching and fiber laser and by combining the strengths of both cutting methods on the Combi machine. Cutting stronger aluminum is done by machining directly from the sheet (working area max. 1500 mm x 2500 mm).

During cutting, the necessary countersinking, threading and shaping in both directions (cups, air holes, reinforcements, pull collars, etc.) can also be made to the sheet.

Lissmac grinding line

With the Lissmac grinding line, we remove sharp edges from the parts on both sides and ensure customer-friendly and safe sheet metal parts.

Prima Power Combi Genius fiber laser enables faster and more economical manufacturing processes for more materials

Brilliant mechanics factory

See also our production methods

Steel and aluminum cutting

We cut sheet metal in a versatile and efficient manner in our own production.

Welding and laser welding

Our production includes versatile welding machines and technology for welding products made from sheet metal.

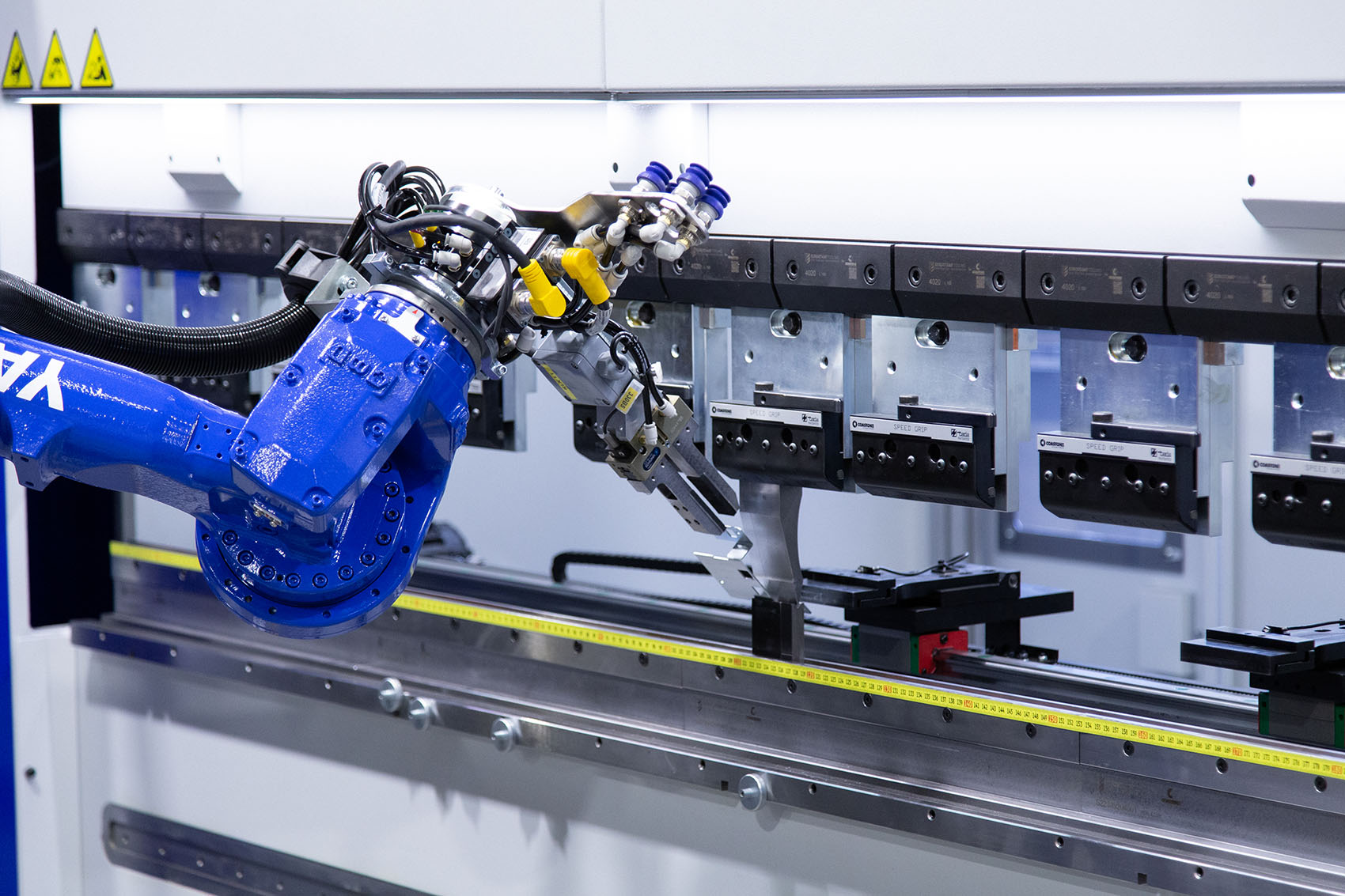

Press-brake bending and clinching

New! We perform press-brake bending and clinching in an automated robotic unit.

Machining

Machining plays an important role in the manufacture of mechanical assemblies.

Coating and painting

We also do coatings and powder coatings for sheet metal products under one roof.

Screen printing and laser marking

Fine texts and graphics on the surface of sheet metal products by printing or laser marking.

Assembly and testing

In addition to high-quality components, we offer our customers mechanical and electrical assembly and testing services.

A reliable partner

We are a challenger of tomorrow who wants to succeed together with our customers today!

Jukka Kotamäki

Sales / Head of Unit

+358 40 501 7799

jukka.kotamaki(at)elekmerk.fi